¶ Running a job

Once you have your design ready to cut, it is time to get the materials prepared and the machine ready to do the job!

- First you will need to get the mat ready.

If you want help with this, check out the guide Using the Machine Mats. - Then you will need to send the design to the machine.

If you want help sending the design to the machine, check out the guide Sending the Design to the Machine.

If you want help changing the tools in the machine, check out the guide Changing the Tools in the Machine. - When the machine is done cutting you can move on to weeding.

Release the mat from the machine by pressing the <-> again.

If you want help with weeding, check out the guide Weeding. - Now that the design is free of extra material, it’s time to move it to its final location!

If you want help transferring stick-on vinyl, check out the guide Transferring a Temporary or Permanent Vinyl Design to a Hard Surface.

If you want help transferring iron-on vinyl or HTV, check out the guide Transferring an HTV Design to Fabric.

¶ Getting the Cricut Machine and Cricut Design Space Connected

This guide is written for someone who has brought their own computer to the space. If you are using a computer provided by the space, it should be set up to work with the machines already.

If you have not already downloaded and installed Cricut Design Space on your laptop, do that now. It is available for Windows, Mac, iOS, and Android. Use their installation instructions for the latest version.

To connect to a new or different machine, you need to add it as if it were a new device.

The Cricuts in the spaces are typically Maker 3. If you’ve got a project open, look in the upper right corner for the toolbar with the Save and Make buttons in it. In the screencap below, the device is already set to Maker 3. Click that to change which machine is set up. If you’ve never used that one before, Cricut Design Space will instruct you on how to connect the machine. The Make button will also start that instruction sequence if the device hasn’t been connected before.

The instruction sequence may look like this →

¶ Using the machine mats

It is important for the material to be held flat and firmly so that the machine can manipulate it. For most materials, this means using a mat to support the material.

¶ Sizing material for the design

Material should be at least an inch larger than the cut size of the design on all sides. So, if a design is 3x4, the material should be at minimum 5x6.

Tip: the alignment of the mat and where the machine thinks the mat is can be off by up to an inch, so it’s important to have extra material to make sure the entire design gets cut out.

¶ Locating material on the mats

The mats have a grid printed on them to help you align the material. Typically material is aligned with the upper left corner of the mat because that is where the design program defaults to placing the design. However, if you are using a piece of material that has been used before or a mat that is losing its stickiness, you can put the material elsewhere on the mat and tell the design program where it is before starting the cutting process.

¶ Sticky mats

Sticky mats come in several sizes and with differing amounts of stickiness.

If present, remove the clear protective cover from the mat.

When applying material to a mat, start by aligning one corner of the material with the markings printed on the mat and then smoothing the material into place working from that corner to the other side. Avoid air bubbles by peeling the material back up if a bubble starts to form and resticking it. You can also use a brayer/roller to push air bubbles to the edge and out.

When removing material from sticky mats, the mat may grip the paper backing of the vinyl strongly enough to tear it. If a tear starts, stop and restart peeling from another corner of the material or peel up the edge of the tear and keep going.

When done with a mat, it is important to replace the protective cover in order to extend the lifespan of the sticky.

¶ Nonsticky mats

Nonsticky mats may be available. To use a nonsticky mat, place the material on the mat, then secure the edges of the material to the mat using masking tape. Make sure that the material is held as flat as possible–no wrinkles or bubbles. The material may not want to lay flat–this is okay, it should be flat without wrinkles or bubbles when held flat.

When done cutting, peel the tape off of the edges of the material and the mat. The masking tape may try to take vinyl with it; be careful to not lose any of your design. Slit the tape to remove material, then peel the tape off of the mat.

¶ Sending the Design to the Machine

When you’re ready, click the Make button in the upper right.

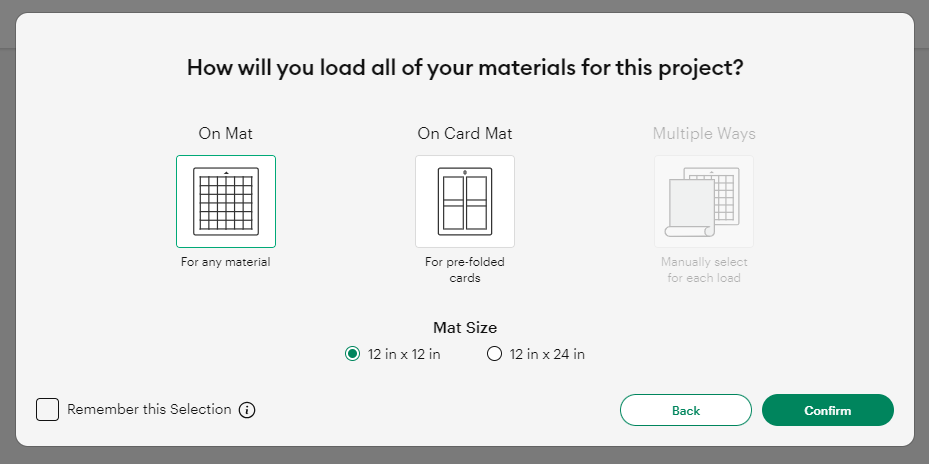

A new window will open. Design Space will ask you what sort of mat you’re using, and then what size.

Once you’ve told it what mat you’re using, click confirm.

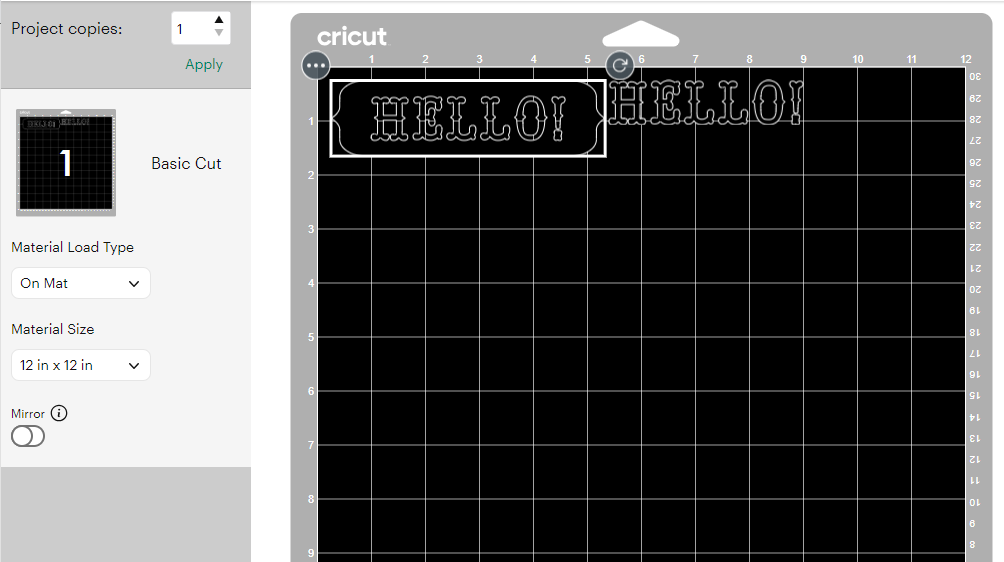

A new window will open. Design Space will show you how your design is laid out on the mat. Here you can click on your design and move it around. Make sure to move the design to match your material location. This is where you select Mirror for HTV designs. If you have multiple materials or cut types, there will be multiple mats to lay out. Be sure to lay out every mat.

Click Continue. A new window will open, helping you connect to the machine. After the machine connects, a new window will open.

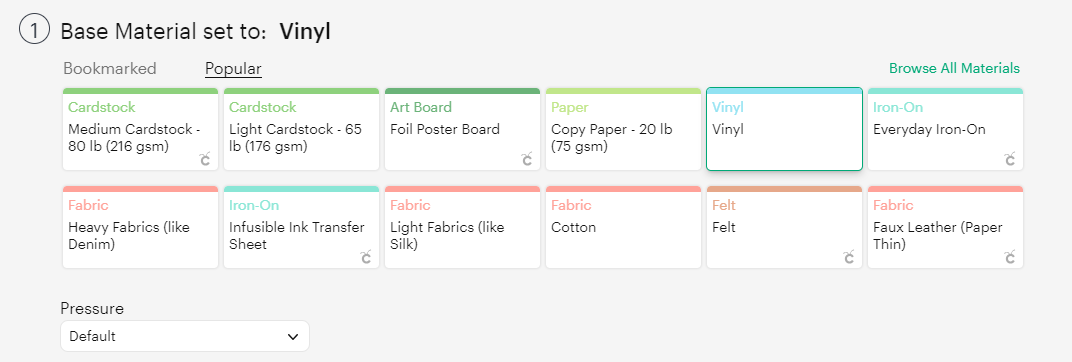

Select what material you’re using.

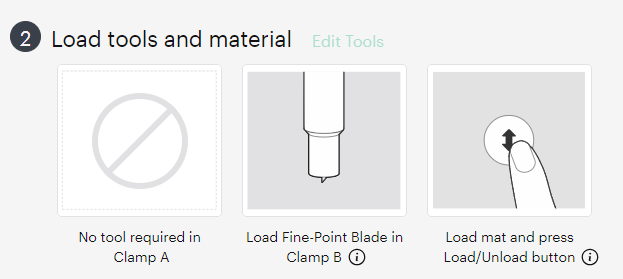

Then it will prompt you to load tools and material.

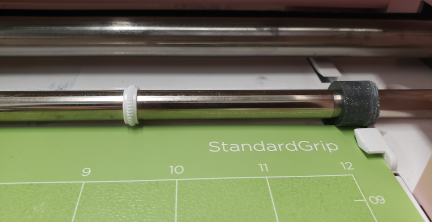

¶ Loading the Mat

To load the mat, align the corners of the mat with the guides and slide it into the machine until it presses against the wheels. Then use the ↕ arrow button on the machine to cause it to load the mat. If the mat loads crooked, use ↕ again to eject the mat. Realign and try again.

¶ Loading the Tool

If you want help changing the tools in the machine, check out the guide Changing the Tools in the Machine on page 8.

Then it will prompt you to press the C button on the machine to start the job.

¶ Changing the Tools in the Machine

There are two tool clamps on the machine. Clamp A (for accessory) on the left and clamp B (for blade) on the right.

To change the tool in clamp A

- Open the clamp leftward

- Lift the tool out

- Insert a tool

- Close the clamp rightward

To change the tool in clamp B

- Open the clamp rightward to release the latch.

- Remove the tool

- Replace the tool. Make sure the collar is resting on the clamp.

- Close the clamp leftward, making sure that the clamp grabs the latch.

¶ Changing the fine point blade

- Remove the tool housing from the machine

- Press the button on the top to extend the blade out the bottom.

- Carefully grip the blade and pull it free.

- Release the button.

- Fold some tape around the blade in order to ‘safe’ it and throw it away/dispose of blade in sharps container.

- Remove protective coating from new blade.

- Carefully grip the new blade by the blade.

- Insert blade into tool housing. A magnet will grab and hold it in place.

- Once secured, replace the tool housing in the machine

¶ Changing the rotary blade

- Remove the tool from the machine

- Place the old protective cap over the blade. This keeps your fingers safe.

- Using the screwdriver that came with the kit/a well fitting screwdriver (in order to avoid damaging the screw), loosen and remove the screw. Keep the screw!!

- Remove the protective cap; the blade and nut will come with the cap. It is safe to discard the old cap.

- Put the new protective cap onto the tool. This will align the new blade and nut with the tool.

- Insert and tighten the screw using the screwdriver. Tighten to just past tight.

- Remove the protective cap. Test the blade by rolling it along the edge of a mat. DO NOT TEST WITH YOUR FINGER. If the blade wobbles side to side, the screw needs to be tightened. If the blade doesn’t roll, the screw needs to be loosened. For tightening or loosening the screw, place the protective cap over the blade to protect your fingers, and use the screwdriver.

- Once the blade rolls smoothly without wobbling, put the tool in the machine or put the cap on and put it in the storage tray.

Ref: https://www.youtube.com/watch?v=lEXHsD_rpV0

¶ Weeding

Weeding is the process of removing unwanted material from a cut design while leaving the wanted material behind. This step happens after cutting and before transferring the design to its final location. Weeding is made easier by having a sharp cutting tool in the machine as that will make better cuts.

The tools used for weeding are typically:

- Picks or weeding pen, to lift the edges of unwanted material

- Tweezer (needle nose and angled), to grab and remove unwanted material

- Scissors, to cut large pieces down and make them easier to handle

- Craft knife, to cut free any pieces that the machine didn’t get

Being careful to not disturb the pieces that you want to keep, use tweezers and/or picks to lift the edges of unwanted pieces with a scooping or hooking type of motion and remove them.

It is important to keep the workpiece flat for the best final product and this is why you should not bend it or use your fingers. It may be helpful to leave the material on the mat while weeding in order to make it sturdier, or to tape it down to the table.

Vinyl and paper weed slightly differently. Vinyl tends to come free very cleanly or tear, leaving a ripply edge. Paper is made up of fibers and especially at corners, there may be fibers that do not get cut all the way through. Simply pulling the pieces free may make the edges look soft and fuzzy, so it’s important to carefully cut those fibers with a craft knife or scissors.

¶ Transferring a Temporary or Permanent Vinyl Design to a Hard Surface

Once the design is cut and weeded it needs to be transferred to its final location. This process is done with transfer tape. The transfer tape is just sticky enough to pick up the design from the backing but not so sticky that it won’t let the vinyl go once the design is pressed into place.

- The surface that the design will be applied to may need to be cleaned. Clean it with rubbing alcohol if rubbing alcohol is safe to use on that surface. Otherwise, scrub with clean, dry paper towel or cloth to remove dust, grease, and fingerprints.

- Apply tape over design. Be sure to cover the entire design. Press the transfer tape down well, starting from the center and working outward to avoid distorting the final design.

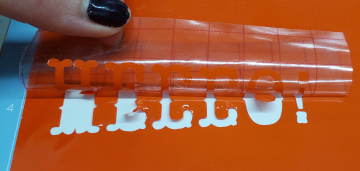

- Peel up the design. Start on one side and work your way towards the other. If any edges don’t come up with the transfer tape, press that area of the transfer tape back down and try again.

- Once you have the design picked up, be careful not to touch the adhesive of the vinyl.

- Align the design with where you want it and place it there. The adhesives of the vinyl and transfer tape should hold it in place for you.

- Press design into place. Work from the center outward to push air bubbles out from under the vinyl.

- Peel off the transfer tape. Start on one side and work your way towards the other. If any edges come up with the transfer tape, press that area of the transfer tape back down and press the vinyl piece extra well before trying again. If the vinyl continues to come up, use a weeding tool to separate the vinyl from the tape and press it onto the surface.

- Discard used transfer tape once it is removed.

- Press the design well using a brayer/roller, spatula, or scraper. Be sure to work from the center outward. Be careful to not scrape up any edges.

¶ Transferring an HTV Design to Fabric

For more on using the heat presses.

Once the design is cut and weeded it needs to be transferred to its final location. Heat Transfer Vinyl has an integrated transfer sheet (carrier sheet), which is the clear sheet covering the color that the design will be once it is transferred.

- Make sure the fabric is laid out flat and smooth on the pressing mat/ironing board.

- Align the design with where you want it to go. The adhesive on the transfer sheet may lightly hold it in place, but do not rely on this.

- Use the heat press with the settings for the HTV you are using programmed in. The settings are usually on the label that comes with the material and can also be looked up on the manufacturer’s website.

Tip: If you are doing a design with multiple colors/layers in it, reduce temperature and time while pressing the earlier layers in order to avoid burning or damaging the vinyl. The last layer can get full heat and time to make sure all layers are properly adhered.

- Once it has cooled to the touch, remove the transfer sheet.

- Wait 24 hours before washing.

Tip: If you are doing a design with multiple colors/layers in it, make sure that no vinyl from the first layer will come into contact with the heat press surface. If the transfer sheet for the second layer is smaller than the first layer, stack the transfer sheet from the first layer on top of the second layer before proceeding.

Tip: If using registration marks, use a piece of heat safe tape or pieces cut from the transfer sheet of the first layer to protect the first layer from the registration marks on the second layer.

¶ Writing and Using Pens with Cricut

Using pens in the Cricut requires tweaking a few settings.

¶ Fonts

Some fonts have a “Writing” version.

In the Style menu where you normally set bold, italic, etc, select “Writing”.

Filter fonts in the font selection area with “Writing” and “Free”

Fonts that don’t have a writing version will draw the outline of the letters as displayed.

¶ Operation type and pen size

Set operation type to pen. Use the box next to the operation type menu to set the pen type and size.

¶ Installing the pen into the Cricut

- Remove cap

- Open clamp A

- Press pen into the holder until the triangle/pen point mark on the side of the barrel disappears into the clamp

- Close clamp A