¶ Introduction

This is an overview of how to mount a wood blank to the lathe for turning. There are three main methods: using a spur center, a chuck, or using a faceplate.

¶ Skills/Class Required

A membership or day pass is required to access the Wood Shop. The following Shop Safety Class is required to access the Jet Wood Lathe:

¶ Machine Reservations

You can make machine reservations in the following ways:

Click to expand

- In person at the front desk.

- Reserve a machine any time through our Mind Body Portal.

- Call the front desk during business hours at (410) 862-0424.

- Email us at frontdesk@openworksbmore.com. Please include your name, the machine you'd like to reserve, and the date(s) and times of the reservation(s).

¶ Before You Begin

Personal Protective Equipment (PPE):

Sturdy, close-toed shoes must be worn at all times.

Long hair, jewelry, and loose clothing must be tied back.

Safety glasses and earmuffs must be worn while machines are running.

A dust mask or a NIOSH certified respirator is recommended.

For more information on shop safety visit Wood Shop under "Safety."

¶ Time to complete

- Less than 10 minutes.

¶ Tools Required

- Ruler.

- Pencil.

- Nail or awl, as needed.

- Bandsaw, as needed.

¶ Materials Required

- Workpiece.

- For more information on compatible stock please visit Jet Wood Lathe under "Material Considerations."

¶ Material Preparation

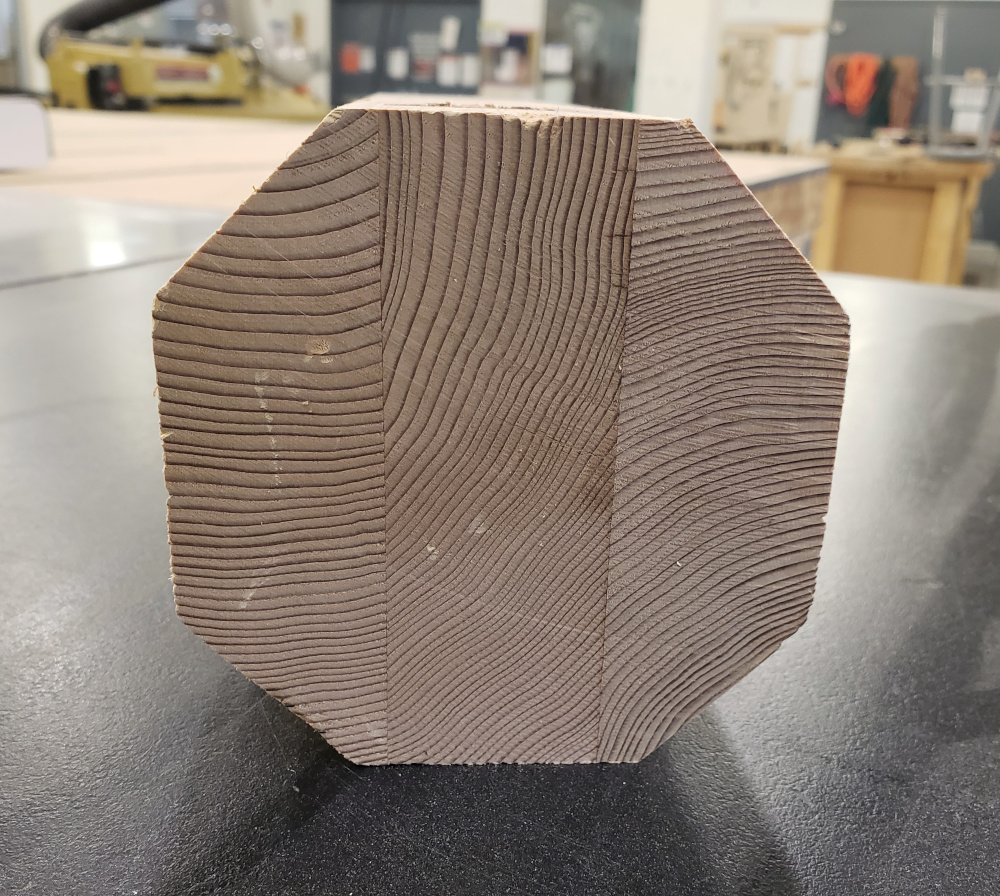

Stock for spindles should be straight grained and free of checks, cracks, knots and other defects. It should be cut 1/8" to 1/4" larger than the finished diameter. It may require additional length that will be removed later for securing the piece. Larger diameter stock and hardwoods should have the corners removed to produce an octagon in order to make the piece easier to rough down to a cylinder.

| This blank is made from three pieces, which is not recommended, but it shows the octagon shape recommended for larger diameter pieces and hardwood. |

|

| Use the table saw to cut the corners off. Set the table saw to 45° and an appropriate fence, and zip those corners off. |

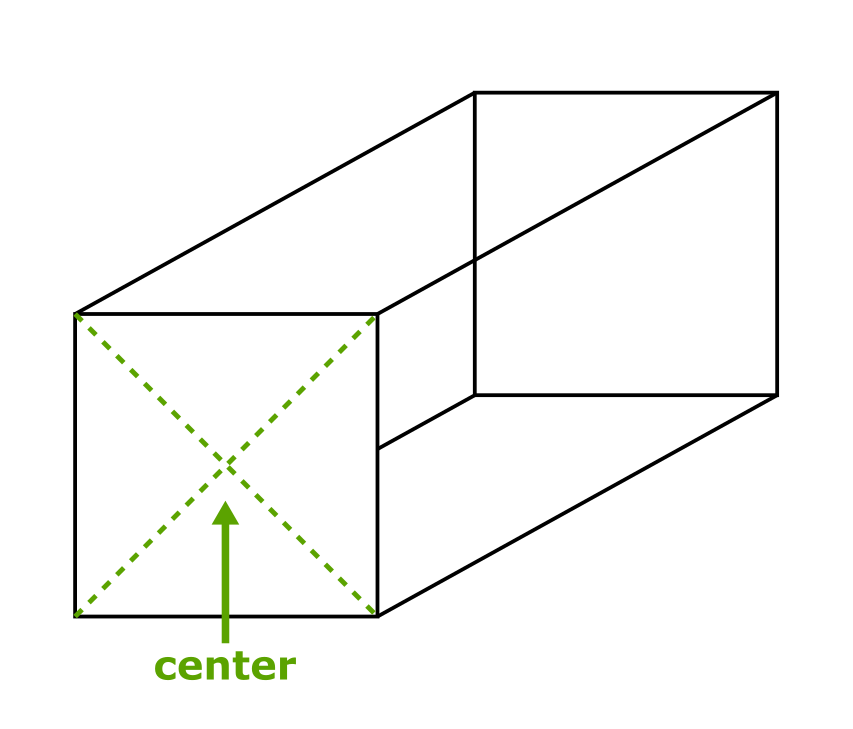

¶ Finding the Center of the Blank

Finding the center is important because it makes the blank easier and safer to work with once it is mounted on the lathe. It is also important because

- Less material to remove to get to round

- If square parts will be kept, getting the round parts and the square parts on exactly the same axis so they look centered.

¶ Finding the center on a blank with an even number of corners

If the blank has an even number of corners (4, 6, 8...), this method will always get the center.

- Using a ruler draw a line from corner to opposite corner.

- The center will be where all of the lines intersect.

¶ Finding the center on a blank with an odd number of corners

- Measure it top to bottom and side to side.

¶ Finding the center on an irregularly shaped blank

- Good luck! (Eyeball it).

¶ Headstock Tools

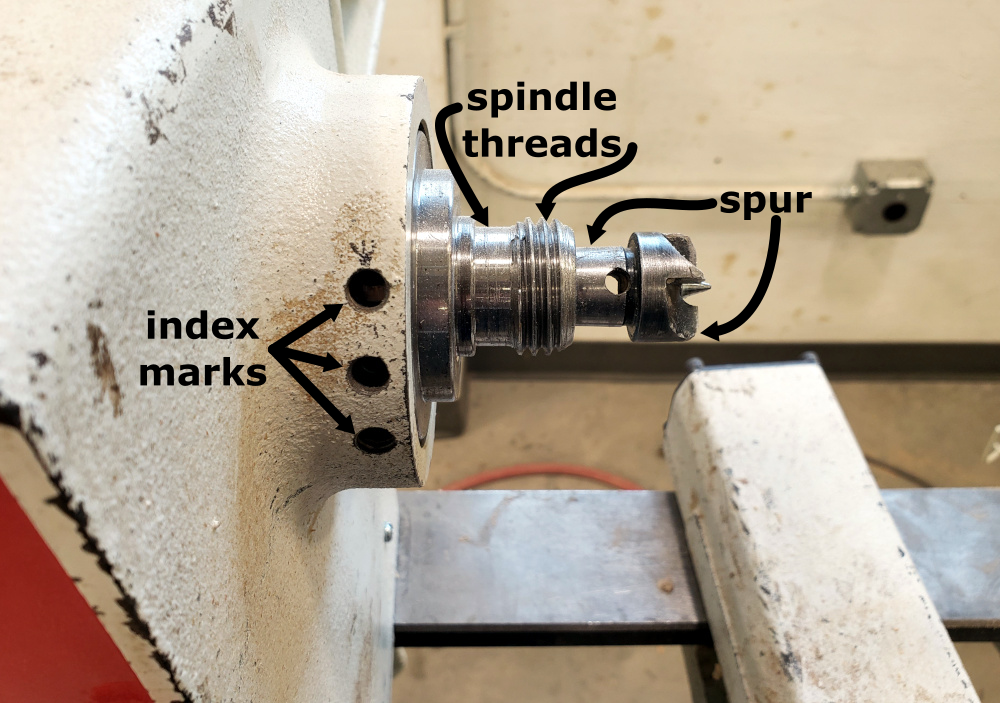

¶ Spur Center

A spur center digs into the blank and requires a live center in the tailstock to use. It will leave a mark on the blank.

¶ Mounting a Spur Center

-

Once you have identified the centers of the blank, put a dimple in center of each end of the blank with an awl or nail.

-

If the wood is soft enough for the spur center to "stick", align it with the dimple and press it in. Tapping it with a wood mallet may help.

If the wood is too hard for the spur to "stick", the blank will require slots cut into the spur center end of stock to hold the flanges of the spur. Cut these slots by using the bandsaw to cut two shallow slots from side to side. They must go through the center and be perpendicular with each other.

Never drive stock onto spur while it is mounted in the lathe spindle.

- Firmly press the spur center into the spindle.

- Support the other end of the blank by bringing up the tailstock with a live center mounted.

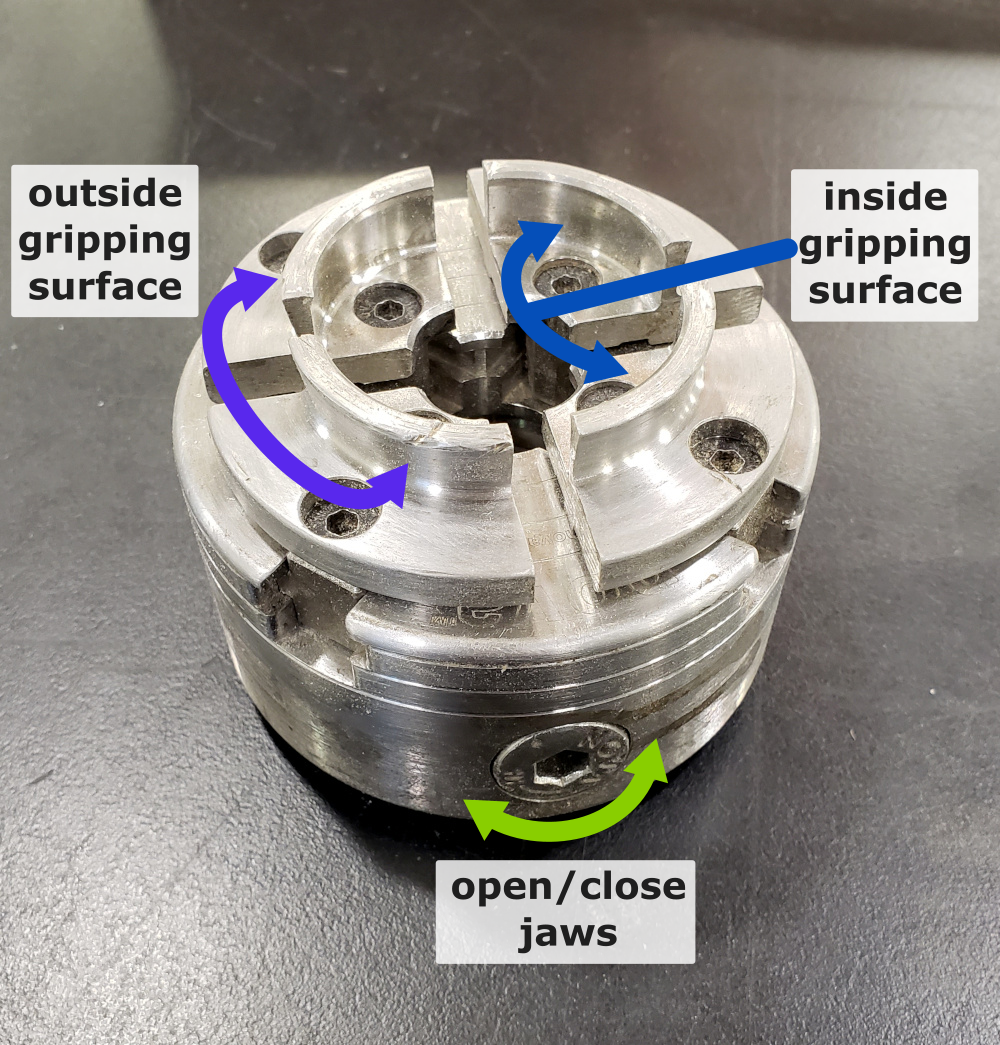

¶ Chuck

A chuck is a device with jaws that function as a clamp. Some chucks have stepped jaws that allow them to clamp from the inside out, not just the outside in. A live center may or may not be used with a chuck, it depends on how much support the blank needs. A chuck is best for blanks that are already round.

¶ Mounting a Chuck

- Thread the chuck onto the spindle.

- Using the Allen key found on the the headstock of the lathe to adjust the jaws to accept the blank.

- Tighten the jaws onto the blank.

- If needed, support the other end of the blank by bringing up the tailstock with a live center mounted.

¶ Faceplate

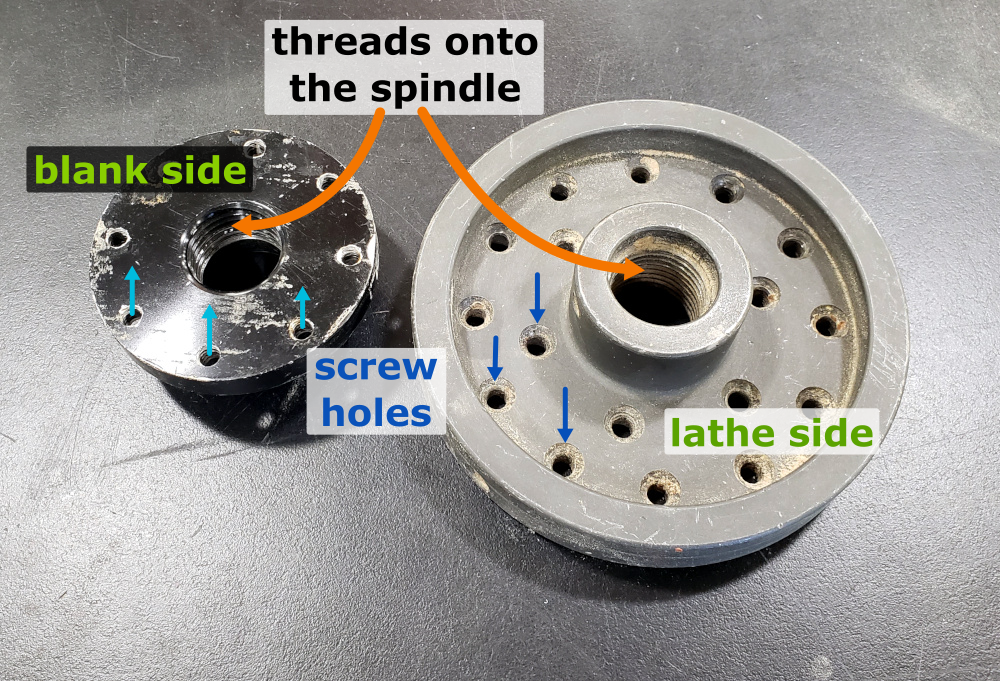

A faceplate is a metal disc that attaches to the spindle to which the blank is fastened with screws. It is best for irregularly shaped blanks. The screwholes will damage the blank. Shown here are two available faceplates. The black one is wood side up and the grey one is lathe side up.

¶ Mounting a faceplate

Collect approximately 6-12 #12 screws from the consumable supplies in the wood shop before you begin.

-

True one surface of workpiece for mounting against the faceplate. It is best to leave extra stock against the faceplate that can be cut off when the workpiece is finished.

-

Using the faceplate as a template, mark the location of the mounting holes, and drill pilot holes of the appropriate size. If the mounting screws on the faceplate interfere with the workpiece, a waste block can be mounted to the faceplate and then the waste block mounted to the workpiece by gluing or screwing.

2.1. Both waste block and workpiece should have good flat surfaces. -

Use a power screw driver or small impact driver to drive screws through the holes in the faceplate and into the blank to secure it.

-

Thread the faceplate and blank onto the spindle.

When turning, be careful to not remove so much material that you hit the screws.

¶ Tailstock Tools

¶ Live Center

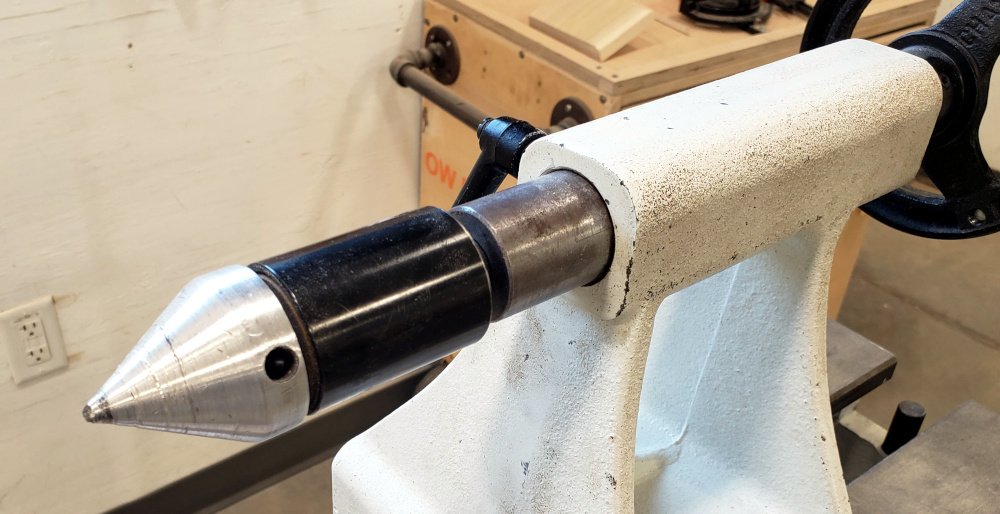

A live center is a tool that supports the tailstock end of the blank. When mounted, it spins freely with the blank as the spindle turns the blank.

¶ Mounting a Live Center

- Unlock the quill.

- Firmly press the live center into the tailstock.

- Loosen the tailstock.

- Move the tailstock up to the blank so that the live center touches the blank. Make sure that if the blank has a center, it's aligned with the point of the live center.

- Lock the tailstock in place.

- Using the handwheel on the tailstock, crank the live center forward so that it presses the blank firmly into/against the drive center.

- Lock the quill.

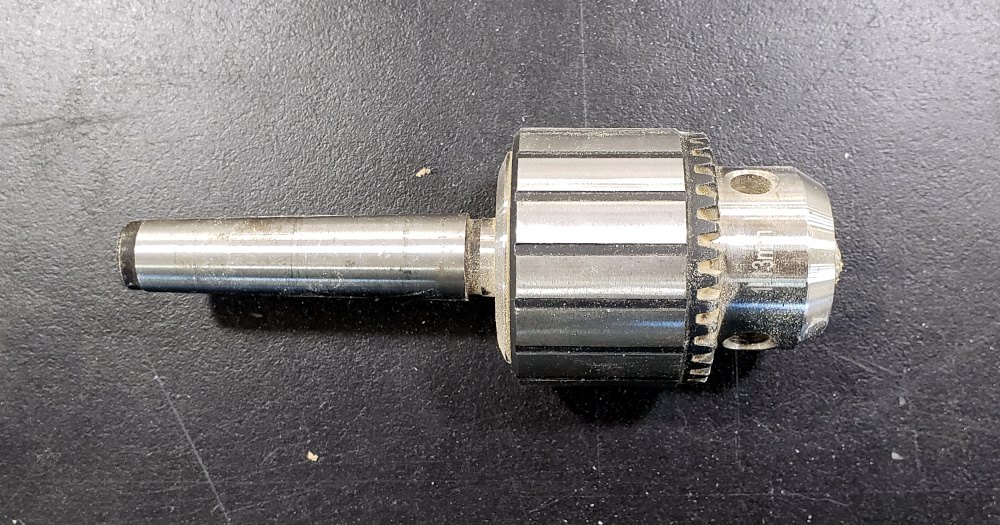

¶ Chuck

A chuck is a tool that holds other tools on the rotational axis. It is often used for holding a drill bit or a router bit in order to create a hole precisely in the center of the work piece.

¶ Mounting a Chuck

- Unlock the quill

- Firmly press the chuck into the tailstock.

- Put the intended tool, such as drill bit or router bit, in the chuck and tighten it.

- Loosen the tailstock

- Move the tailstock up to the blank so that the end of the inserted tool ALMOST touches the blank. Make sure that if the blank has a center, it's aligned with the point of the tool.

- Lock the tailstock in place.

- Using the handwheel on the tailstock, make sure that you can crank the tool forwards and back.

¶ Using the chuck

- When the lathe is spinning, use the handwheel on the tailstock to drive the tool into the material.

- Retract the tool before turning off the lathe.

¶ The Tool Rest

The tool rest provides a steady platform for you to brace your hand and tool against, making it easier to control the tool against the workpiece.

¶ Adjusting the Tool Rest

The tool rest and tool rest carrier both have handles that lock and unlock them.

- Unlock the tool rest and tool rest carrier.

- Adjust the tool rest and tool rest carrier until the tool rest is parallel to workpiece, approximately at the centerline and approximately 1/8" from the closest part of the workpiece.

- Lock tool rest body and tool rest in place.

- Rotate workpiece by hand to check for proper clearance from tool rest and make changes as needed.

¶ Removing Stuck Tools

Occasionally the spur center or any of the tailstock tools may get stuck. They are removed by %%Details.