¶ Introduction

Milling is a cutting process that uses a milling cutter to remove material from the surface of a workpiece. The milling cutter is a rotary cutting tool, often with multiple cutting points. As opposed to drilling, where the tool is advanced along its rotation axis, the cutter in milling is usually moved perpendicular to its axis so that cutting occurs on the circumference of the cutter. As the milling cutter enters the work piece, the cutting edges (flutes or teeth) of the tool repeatedly cut into and exit from the material, shaving off chips (swarf) from the work piece with each pass. The cutting action is shear deformation; material is pushed off the work piece in tiny clumps that hang together to a greater or lesser extent (depending on the material) to form chips. This makes metal cutting somewhat different (in its mechanics) from slicing softer materials with a blade.

The milling process removes material by performing many separate, small cuts. This is accomplished by using a cutter with many teeth, spinning the cutter at high speed, or advancing the material through the cutter slowly; most often it is some combination of these three approaches.[2] The speeds and feeds used are varied to suit a combination of variables. The speed at which the piece advances through the cutter is called feed rate, or just feed; it is most often measured as distance per time (inches per minute [in/min or ipm] or millimeters per minute [mm/min]), although distance per revolution or per cutter tooth are also sometimes used.

There are two major classes of milling process:

- In face milling, the cutting action occurs primarily at the end corners of the milling cutter. Face milling is used to cut flat surfaces (faces) into the work piece, or to cut flat-bottomed cavities.

- In peripheral milling, the cutting action occurs primarily along the circumference of the cutter, so that the cross section of the milled surface ends up receiving the shape of the cutter. In this case the blades of the cutter can be seen as scooping out material from the work piece. Peripheral milling is well suited to the cutting of deep slots, threads, and gear teeth.

¶ Shop Access

A membership or day pass is required to access the Metal Shop

The Shop Safety Class Metal 1: Shop Safety is required to access the Metal Shop.

The milling machine is not currently covered by any Shop Safety Classes at Open Works.

Please see a Community Technician to be trained on the milling machine!

¶ Machine Reservations

The milling machine does not require a machine reservation and is available on a first-come first-serve basis.

¶ Parts of the Machine

Click to expand

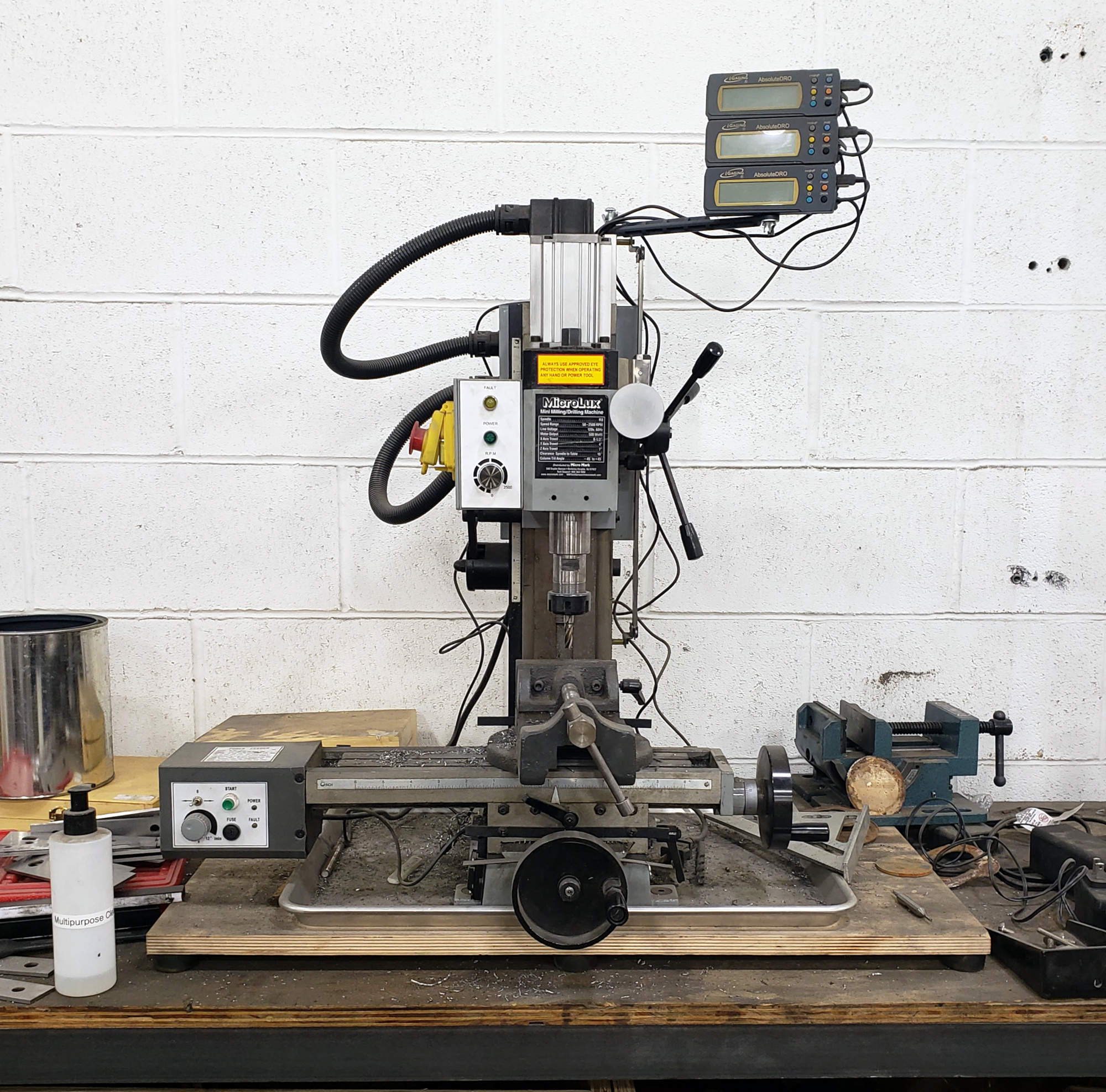

%%INSERT PICTURE¶ Material Considerations

¶ Acceptable Materials:

Mild steel

Stainless steel

Brass

Aluminum

Copper

¶ You can do it but we'd prefer if you didn't:

Woof

¶ Forbidden Materials:

Anything with toxic coatings

Tool steel

¶ Safety

Personal Protective Equipment (PPE):

• Sturdy, close-toed shoes must be worn at all times.

• Long hair, jewelry, and loose clothing must be tied back.

• Safety glasses and earmuffs must be worn while machines are running.

For more information on shop safety Safety on the Metal Shop page.

¶ Step-by-Step Guides

¶ Before You Begin

Understand the feeds and cutter speeds you may need for the material.

¶ Using the Machine

Take it easy and lubricate the cutter often.

¶ Machine Maintenance

All machine maintenance pages are only accessible to Staff. All machine maintenance is only to be done by Staff.

- Clean up all chips, dust, and debris.

- Oil or wax the bearing surfaces.

¶ Troubleshooting

All troubleshooting pages are only accessible to Staff. All troubleshooting is only to be done by Staff.